OUR PROCESS

MANUFACTURING PROCESS

At J&K Engineering Works, manufacturing is not just production—it is a craft built on precision, engineered for reliable connections, and driven by continuous innovation. Every brass terminal and connector we produce carries this philosophy from design to delivery .Established in 1982 in Faridabad, Haryana (India), J&K Engineering Works is a leading manufacturer, exporter, and supplier of precision-engineered components.

The company specializes in:

Brass Terminals

Plastic Connectors

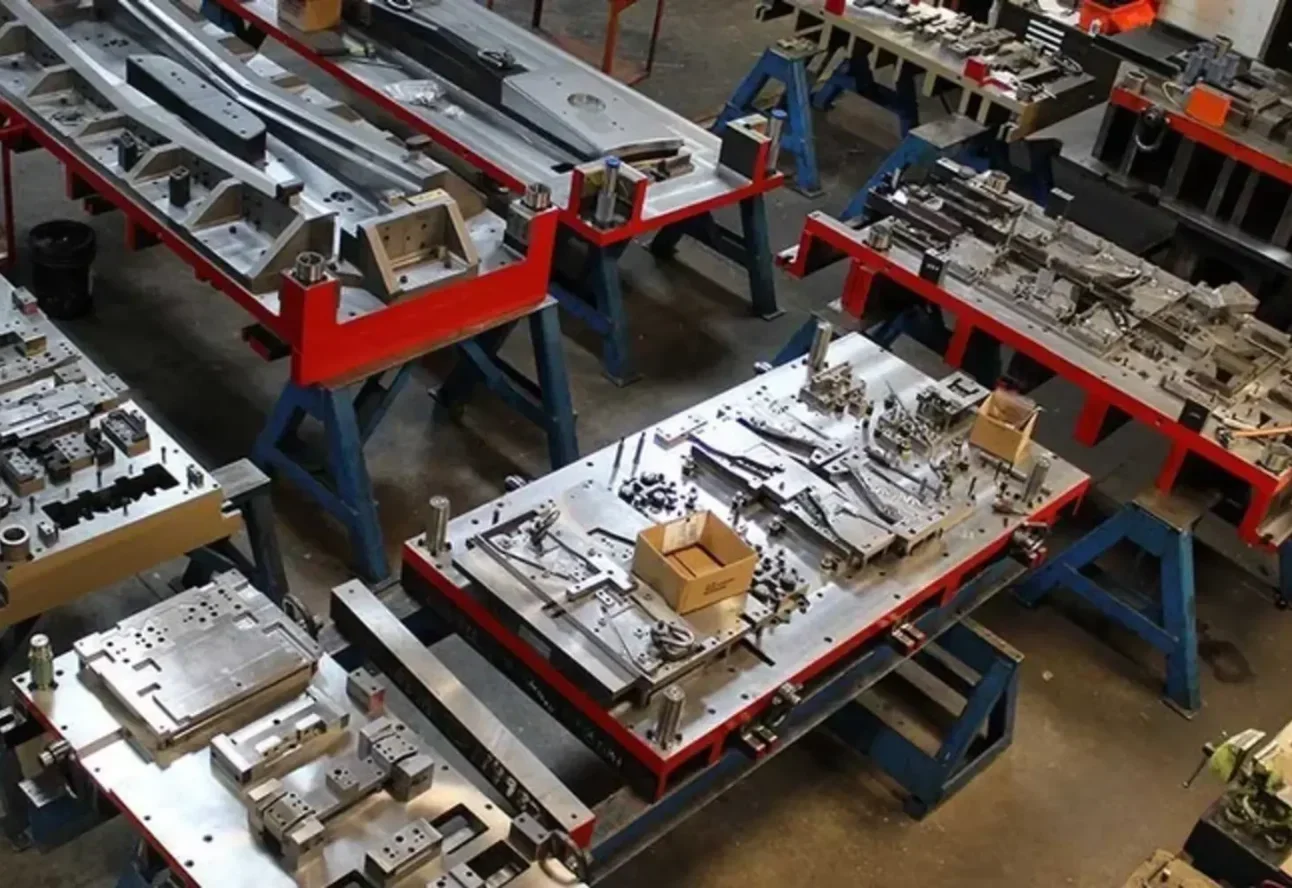

Dedicated Tool Room – The Foundation of Precision

The process begins in our dedicated tool room, equipped with advanced machinery and staffed by experienced specialists. Our engineers design and manufacture custom dies and moulds tailored to exact specifications, ensuring accuracy and reliability.

Each tool is engineered for durability and consistent performance, while regular calibration maintains dimensional integrity throughout production. With their expertise, our team transforms complex designs into precise, high-performing tools that form the backbone of efficient manufacturing.

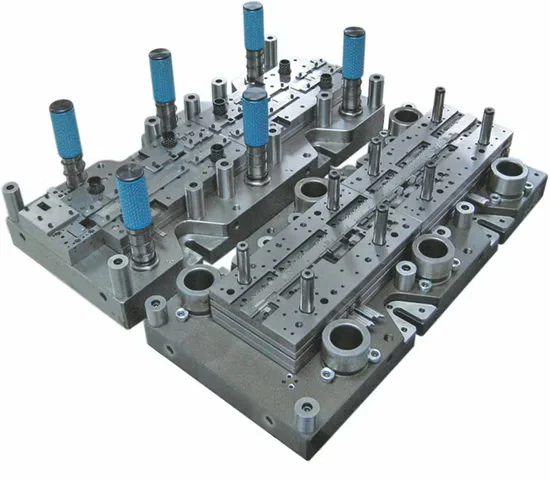

Die Mould & Setup

The specially developed dies are integrated into production machines with meticulous alignment, ensuring error-free operation and seamless workflow. This step strengthens the connection between design and production, guaranteeing consistency across every batch.

PRODUCTION CAPACITY

With over 40 years of expertise, J&K Engineering Works has established itself as a trusted name in high-volume, precision manufacturing. Our infrastructure is designed to balance scale, accuracy, and efficiency, enabling us to meet the evolving needs of industries worldwide.

50+ Skilled Professionals

A dedicated workforce ensures consistency, quality, and productivity across all stages of manufacturing.

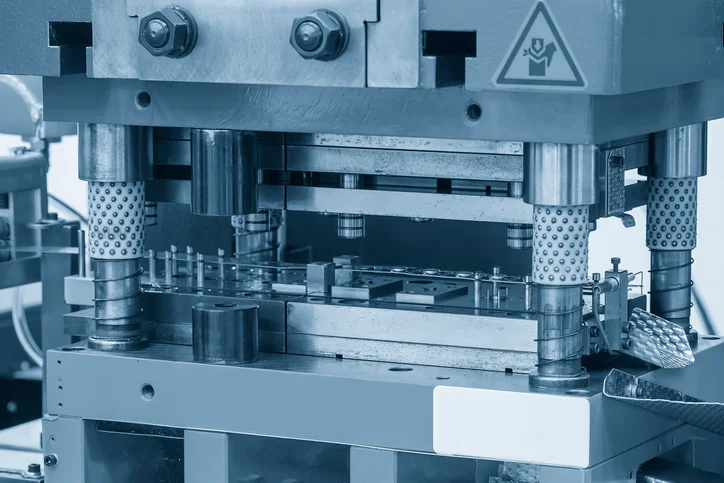

Metal Stamping Machines

Our stamping division delivers high-output production of brass terminals and components. These machines are capable of maintaining tight tolerances, ensuring each piece meets strict dimensional and quality standards.

Plastic Moulding Machines

Advanced moulding systems allow us to produce durable plastic connectors, providing seamless integration with our brass terminals.

1 In-House Tool Room

A fully equipped tool room supports die design, maintenance, and calibration. This ensures:Faster turnaround for new product development.

Reduced downtime through regular tool maintenance.

Long-term reliability and consistency in mass production.

LEGACY OF EXCELLENCE

Backed by four decades of continuous service, J&K Engineering Works continues to deliver on its promise of Precision | Connection | Innovation, serving industries across automotive, electrical, electronics, appliances, and beyond.